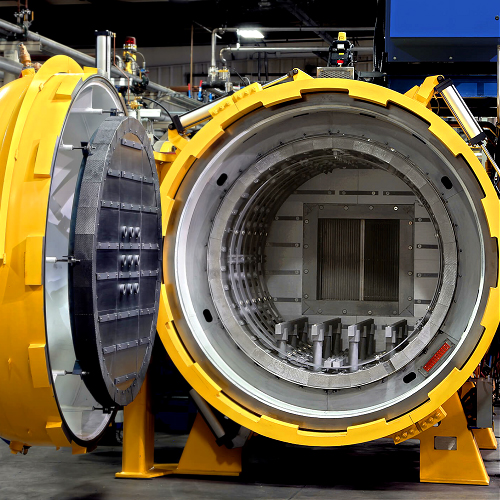

Vacuum gas quenching furnace

- Overview

- Parameter

- Inquiry

- Related Products

The rapid cooling of materials can be achieved by using vacuum technology and gas cooling technology, which can quickly reduce the material temperature from high temperature to below room temperature in a low-pressure, high-temperature environment, significantly improving production efficiency and workpiece performance.

Since the vacuum gas quenching furnace can make the surface and internal material structure of the workpiece reach a highly uniform quenching state, the performance and stability of the workpiece after heat treatment are higher. In addition, the vacuum gas quenching furnace can effectively avoid quality problems such as deformation, cracking, internal defects, etc. caused by uneven cooling medium, making the workpiece quality more reliable.

Quenching in a vacuum environment can avoid oxidation and decarburization of the workpiece surface and maintain the smoothness and precision of the workpiece surface.

Using high-purity inert gas (such as helium or nitrogen) as the cooling medium does not pollute the surface of the workpiece. The surface cleanliness of the treated parts is high, and there is no need for post-cleaning and shot blasting processes. It belongs to the clean heat treatment technology.

It is suitable for high-value materials such as high-speed steel, stainless steel, titanium alloy, etc., and can be vacuum tempered to further improve the performance and quality of the workpiece.

| Item | Parameter |

|---|---|

| Diameter Range | 80mm~600mm |

| Pipe Length | 1-10m |

| Material | Silicone cloth / non-woven / canvas |

| Fabric Thickness | 0.2-0.3mm |

| Fabric Width | 110mm |

| Metal Strip Width | 11mm |

| Metal Strip Thickness | 0.4-0.5mm |

| Motor Power | 2.2KW |

| Forming Speed | 1-15 m/min |

| Weight | 500KG |

| Dimension | 2200 X650 X1200mm |